This course provides students with opportunities to apply a design process to meet a variety of technological challenges. Students will research projects, create designs, build models and/or prototypes, and assess products and/or processes using appropriate tools, techniques, and strategies. Student projects may include designs for homes, vehicles, bridges, robotic arms, clothing, or other products. Students will develop an awareness of environmental and societal issues related to technological design, and will learn about secondary and postsecondary education and training leading to careers in the field.

To watch the Course Selection Technological Design Q & A meeting recording here.

SATEC’s Project Gallery:

|

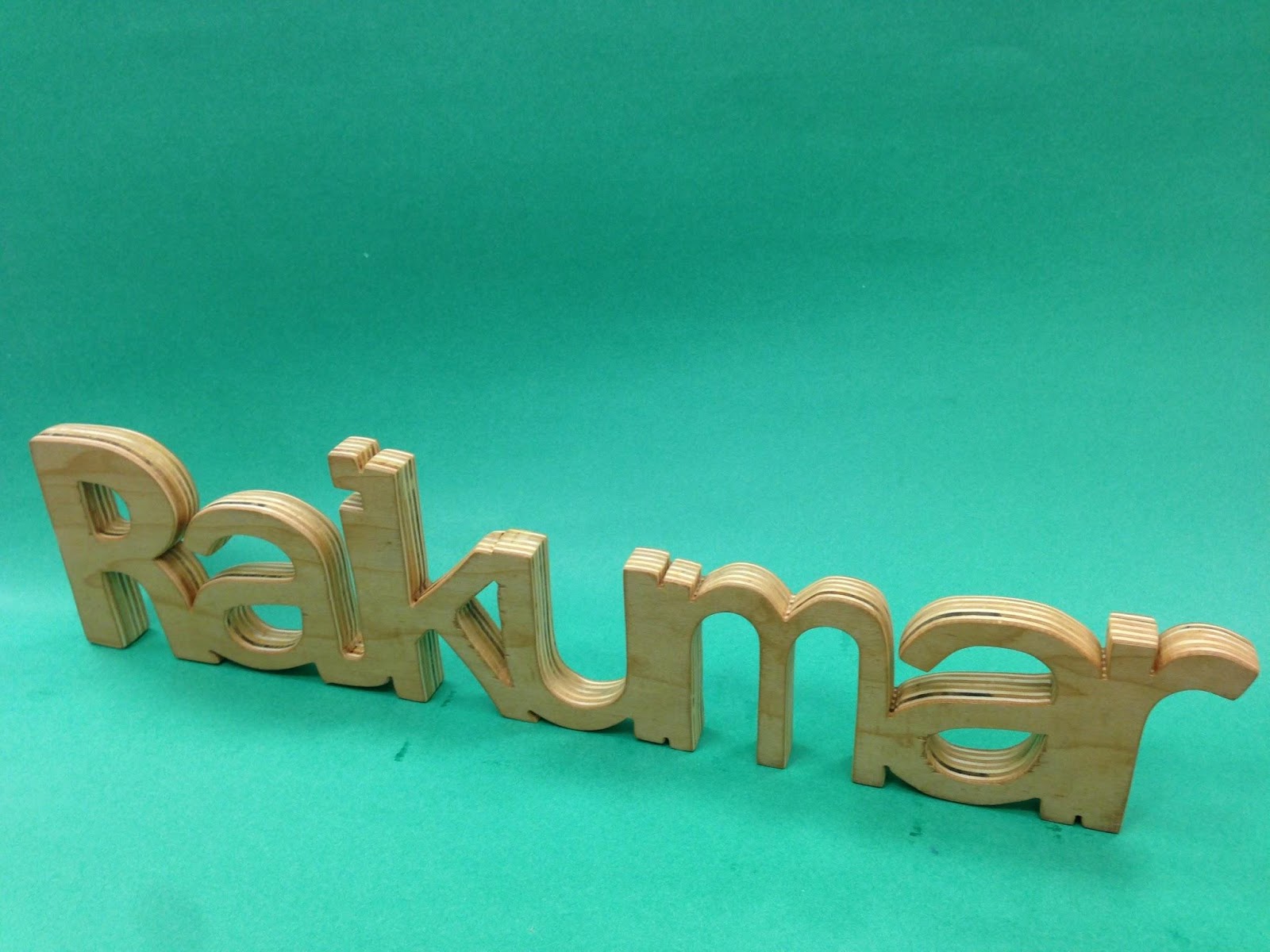

WOODEN LETTER

WOODEN WORD

|

Our ‘warm up’ project!

Initial projects, such as this, introduce our students to…

- the design process

- wood theory

- general workplace & woodshop safety

- production of technical drawing

- scale, proportion and measurement

- hand tool skills

- woodshop equipment skills (belt/disk sander, drill press, scroll saw, band saw)

- wood finishing skills

|

|

|

|

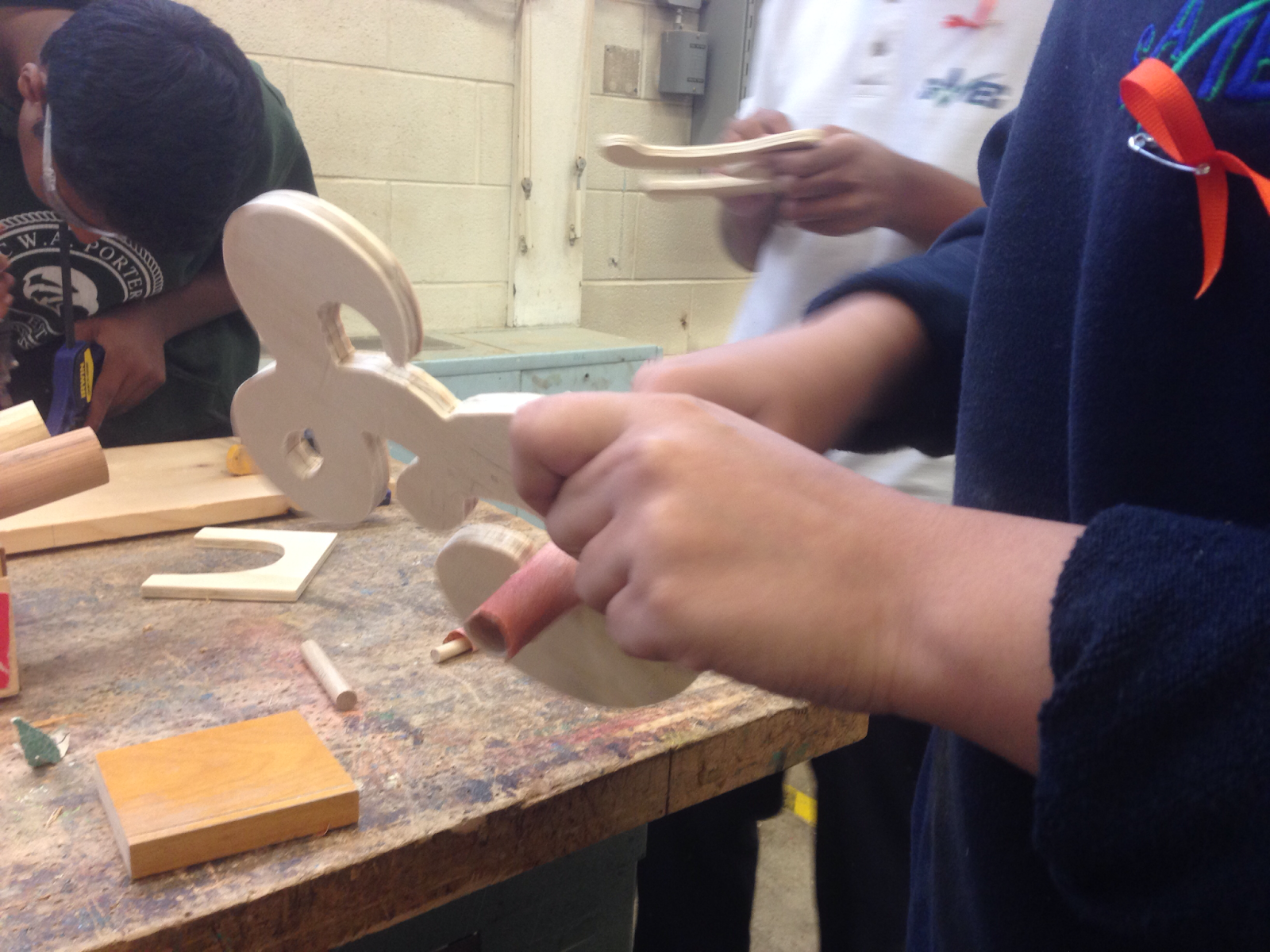

CO2 DRAGSTER

|

The CO2 Dragster is one of our most popular projects. It focuses on the principles of vehicle engineering. Students research scientific topics inclusive of aerodynamics, drag, friction, etc. Then we watch real dragster videos, seek out images of car designs and blend this inspiration into our own concept dragster designs. We begin by hand sketching. These designs are then transferred into 3D AutoCAD or Inventor Pro. Wind tunnel testing followings. Depending on the results, alterations to the designs are considered. From here, we go into the woodshop to make our ideas come to life! It is in the woodshop that real problem solving skills come to play as we attempt to execute, with accuracy, our own design intentions. After sanding, sanding and more sanding of our dragsters, we are almost ready to race.

RACE DAY setup is an excellent example of all students working together to prepare for the big event. Statistics are recorded on the blackboard, students vote for who they think will win (based on our recently acquired knowledge) and results are tallied.

RACE DAY is awesome fun!

|

|

Race Day Videos:

|

|

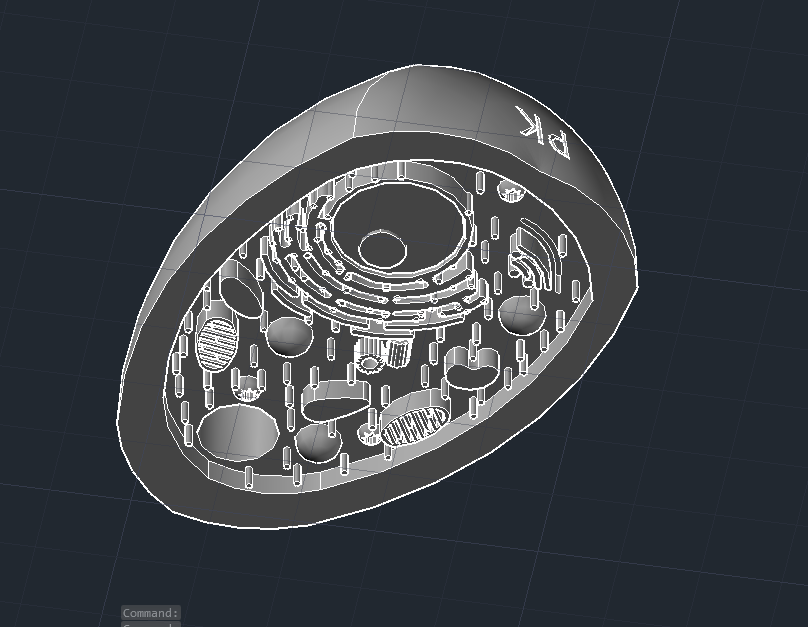

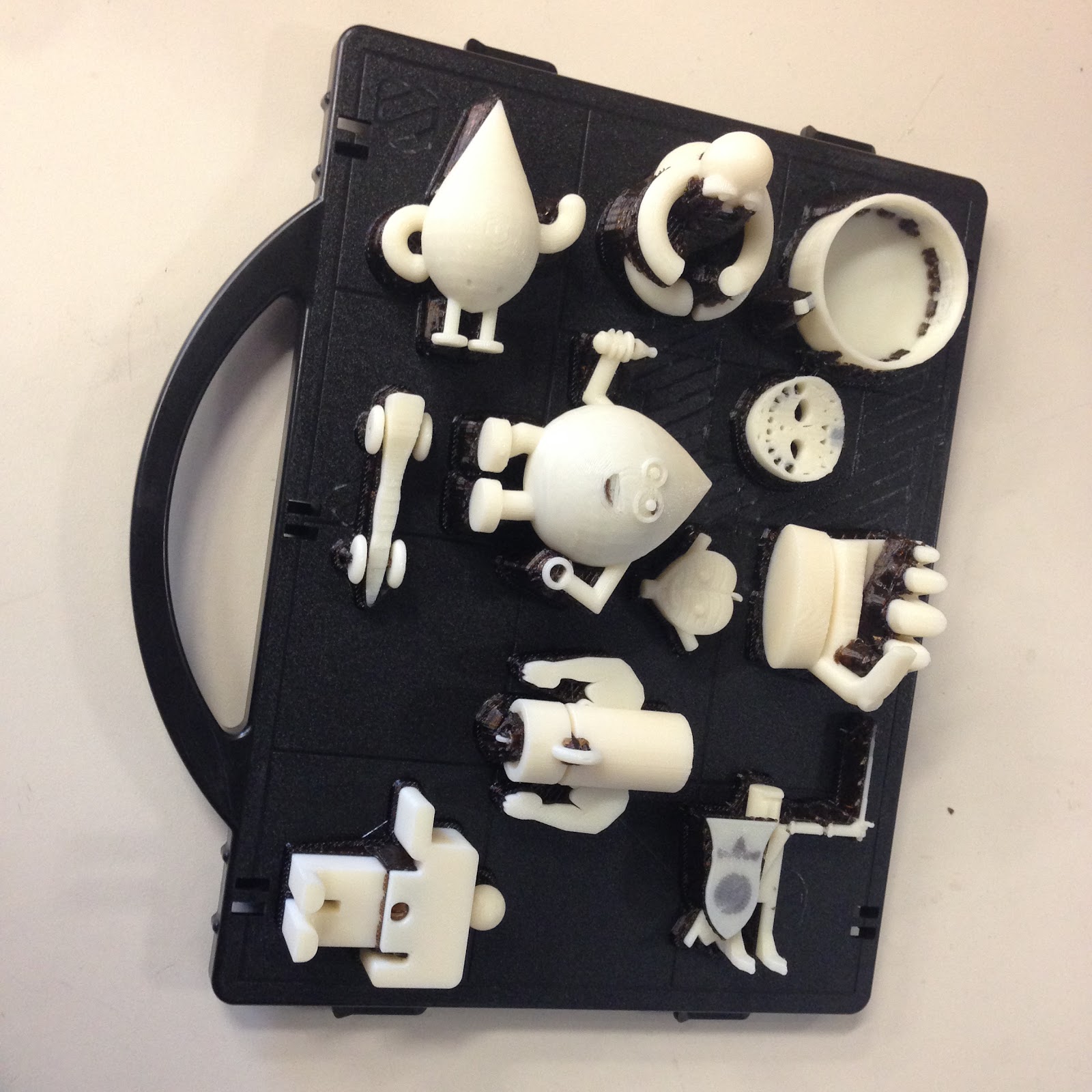

3D PRINTING

(ADDITIVE MANUFACTURING)

|

Here at SATEC we believe that 3D Printing is an integral technology for our existing society, and it will continue to be even more important in the future. 3D Printing touches almost every aspect of our lives… healthcare, transportation, hospitality and tourism, architecture and so on!

Each year our students explore different themes and create their own ‘keychain’ designs. In the past we have created ‘environmental mascots.’ These mascots were designed to promote care and consideration for our environment both close to home and abroad. In the spring of 2017, we explored the theme of ‘careers’ and asked ourselves... ‘How is 3D Printing incorporated into aspects of our future jobs?’

Can you guess what these students hope to study and work at in the future?

|

|

|

|

CEDAR PLANK PROJECT

|

The cedar plank project is simple… each student receives a 6” x 18” cedar plank with which they must employ the design process to create a unique, useful product.

Steps involved:

- Concept design

- Technical drawing

- Measuring and marking the wood

- Building the project in the woodshop

- Finishing by sanding and oiling

- Creating a portfolio sheet

- Reflecting on our learning & discussing transferable skills

|

|

|

|

TREEHOUSE ARCHITECTURE

|

As a child we have all dreamt of climbing up into a treehouse to enter an imaginary world. It is this freedom to imagine that inspires our treehouse model designs here in the SATEC TDJ2O classroom.

By researching environmentally conscious architectural principles, such as thermal massing, greenhouse effect, solar orientation, solar shading and prevailing wind protection by trees, stack effect, green roofs, etc., we begin to understand that good design is well considered design. Adding to this knowledge, we then explore cool treehouse designs from around the world to feed our imagination. Scale and proportion mean everything to the treehouse experience; we measure ourselves ‘acting out’ our programming needs - sleeping and sitting outside having a hot chocolate. Once we know how tight our spaces have to be, we are ready to design!

Off we go to create design sketches, technical drawings and final scale models of our dream ‘home’ floating up and away in the leaves...

|

|

|

|

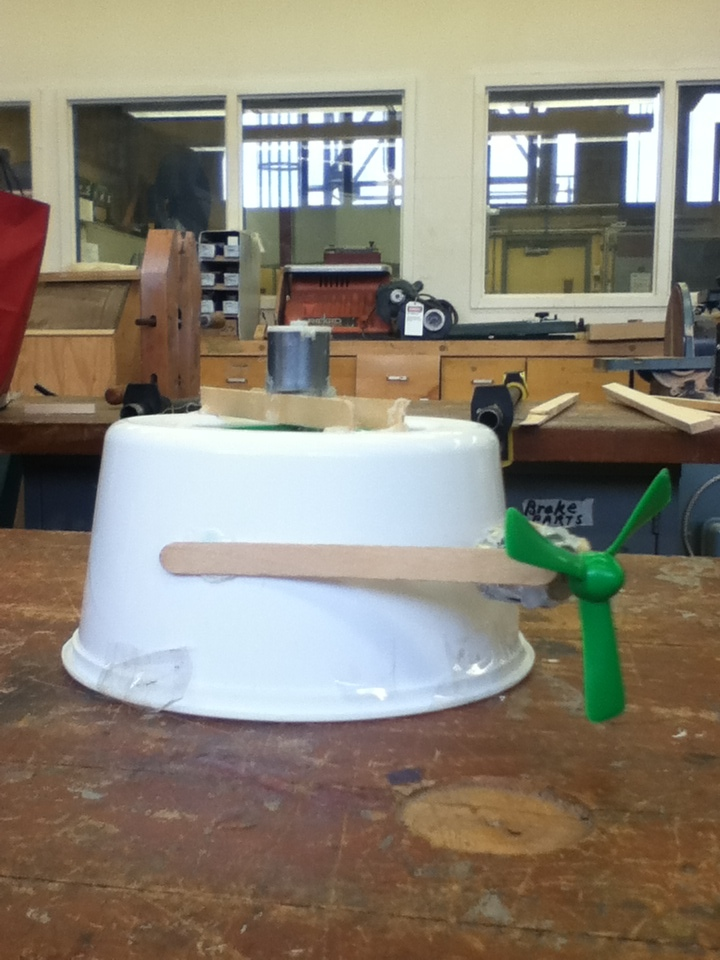

HOVERCRAFT

|

The Hovercraft project is a blend of engineering principles, understanding materiality and creative problem solving. Students research and design their concept Hovercraft. Inventor Pro is used to create technical drawings. From here, it is into the wood shop to build prototypes.

Do you think they hover? It is a challenge that is not as easy as you may think to solve...

|

|

|